Corrosion resistant and maintenance-free chains

ELITE roller chains contain all common coating, such as stainless steel, zinc or nickel-plated variants, which are all available in a large number of roller chains. Corrosion-resistant chains are treated with low-viscosity oil as standard, which not only provides basic initial lubrication but also allows better drainage and easier cleaning of roller chains.

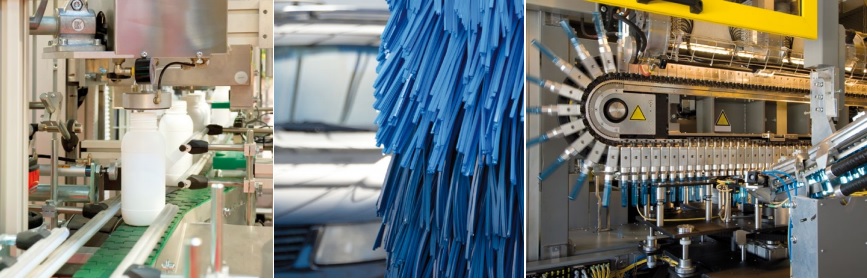

Industries and applications:

- Food and beverage industry

- Packaging industry

- Cleaning and washing technology

- Conveyor technology

- Textile machinery and clothing industry

- Electronic industry and circuit board manufacture

- General engineering and plant construction

- Solar power and energy technology and much more besides

ELITE stainless steel chains (CF)

Stainless steel chains are used mainly in the food and beverage industry or for applications in which chains require regular cleaning. The materials used in ELITE chains enable them to be used in acidic or alkaline environments. Always ensure that the chemicals in cleaning agents used are compatible with stainless steel material number 1.4301. The permitted tensile load for stainless steel chains is approximately one-third of the permitted load for comparable standard ELITE chains.

Zinc-plated ELITE chains (ZP)

Zinc-plated chains are used primarily in outdoor applications where there is no protection against adverse weather conditions. Zinc protects the chain against rusting in two different ways. Firstly, the zinc forms an unbroken layer around chain components to prevent water, salt and oxygen from coming into direct contact with the steel link plate; secondly, zinc acts as a “sacrificial anode” in the event of damage to the chain and protects important load-bearing components against corrosion.

Nickel-plated ELITE chains (NP)

Nickel-plated chains are used mainly in the food and packaging industry; the characteristic properties of nickel make it a particularly suitable coating metal for numerous applications. It is impervious not only to water and air but also to a variety of acids and alkalis.

Maintenance free roller chains

Maintenance free roller chains have longer service life and better wear resistance. The sinter materials used in their manufacture have been upgraded and improved so as to make the new, black coated roller chains significantly more resistant to wear without the need for re-lubrication.

We offer corrosion resistant and maintenance free roller chains according to ISO 606 British (BS) and American (ANSI) standard: 04B, 05B, 06B, 08B, 10B, 12B, 16B, 20B, 24B, 28B, 25SS, 35SS, 40SS, 50SS, 60SS, GL08B, GL10B, GL12B, GL16B, GL20B, GL24B, GL28B, GL32B, 40ZP, 50ZP, 60ZP, 80ZP, 100ZP, 120ZP, NP, EVP and ect.